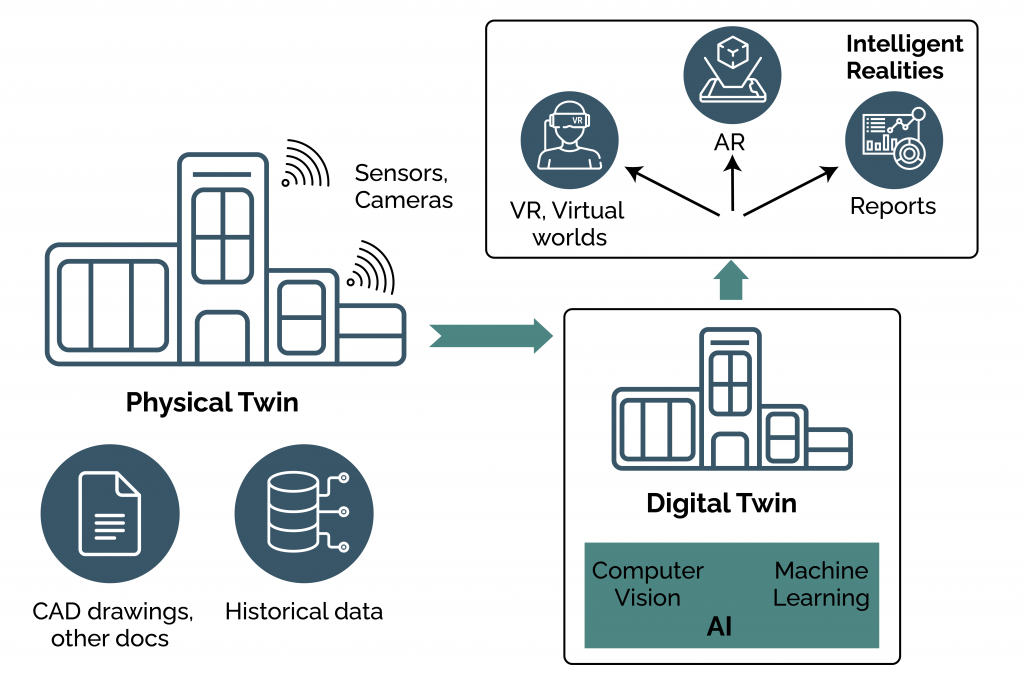

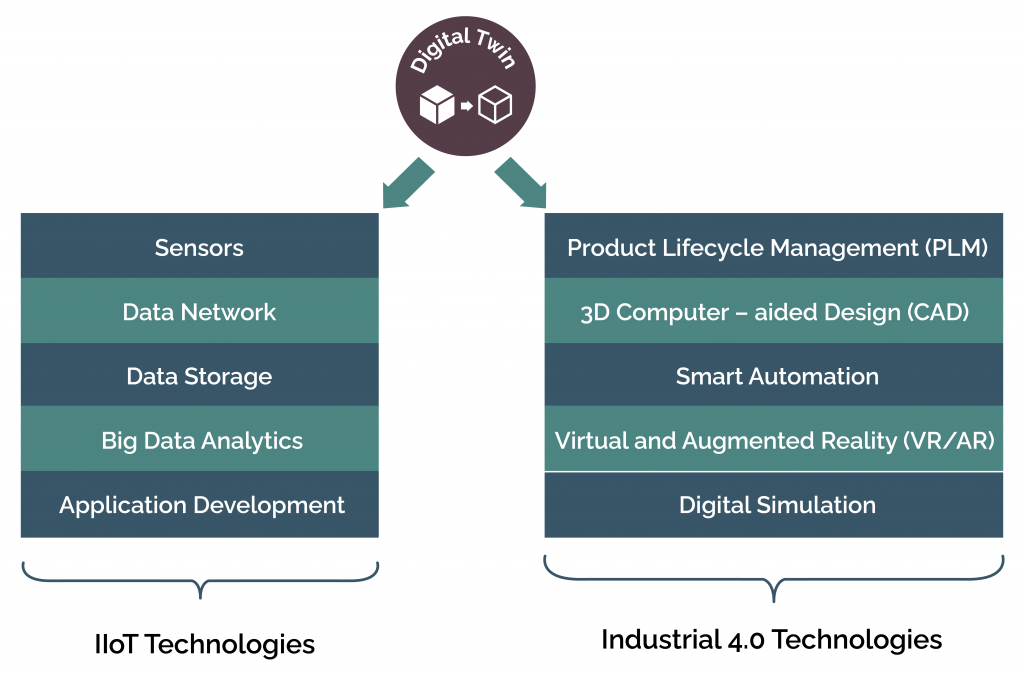

Most enterprises aspire to be digitally transformed. Innovation as the engine of growth favors this initiative, especially in the immersive technologies space. A core enterprise priority now is to deliver new customer experiences through digital products and services. This mandates the collection and analysis of operational data used to make process adjustments for cost reduction, efficiency improvement, and reliable business outcomes. The biggest challenge today is deploying disparate technologies within a unified business function.

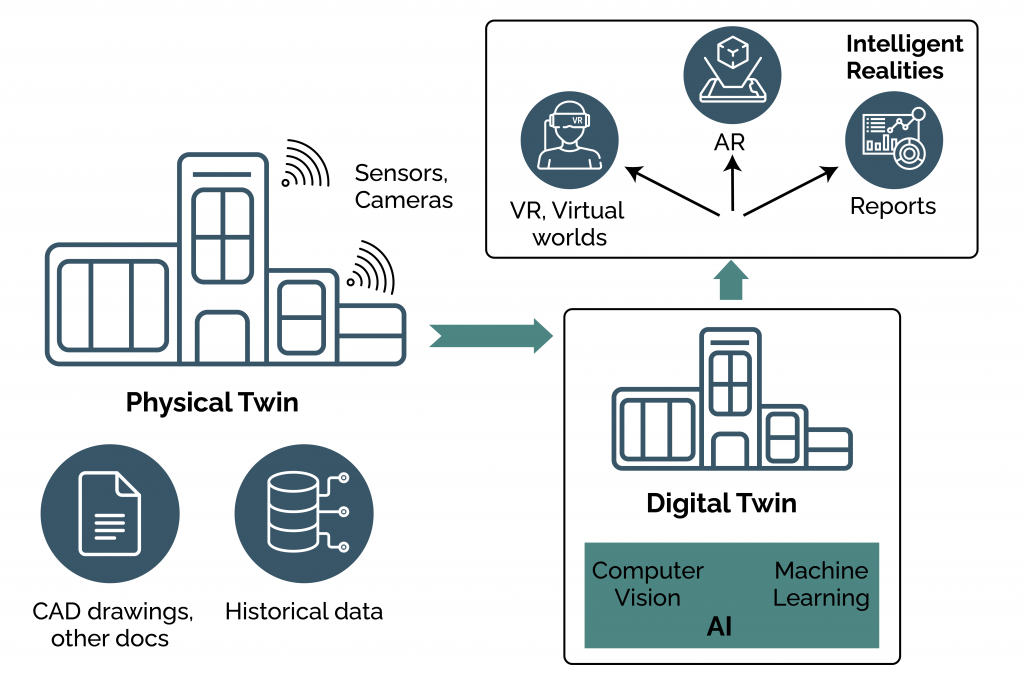

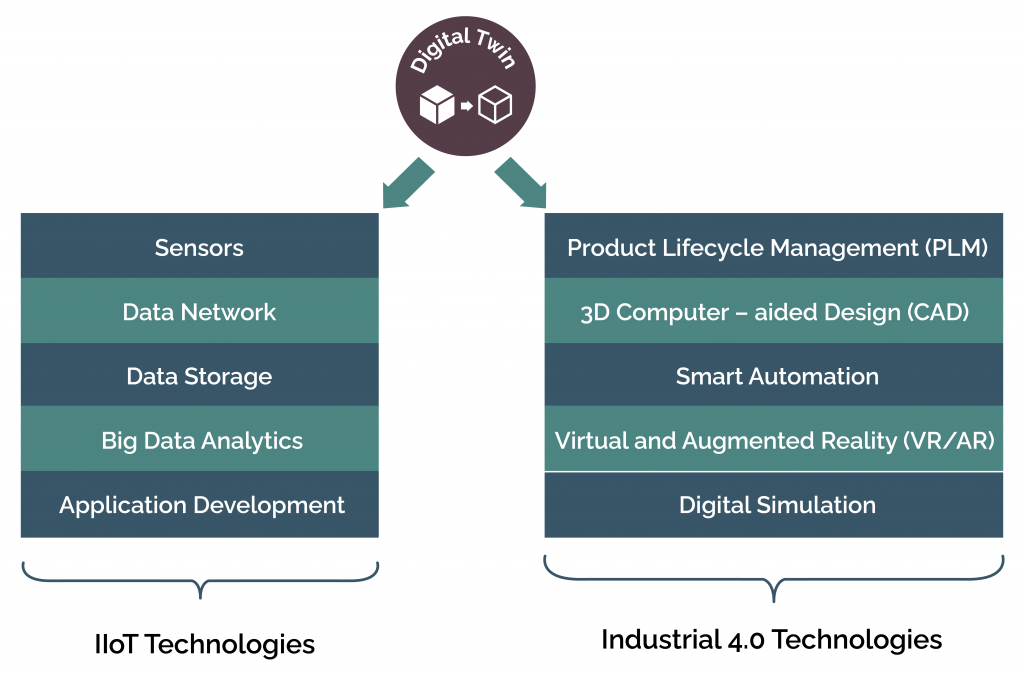

This helps identify and isolate issues and deploy fixes. Using the Digital Twins, iterations are made cost-efficient and less time-consuming. Digital twins also help position companies for next-gen computing that is interactive, spatial, and intelligent. All of which is pivotal to Immersive experiences provided by AR.

All the products and processes have a digital identity with unique characteristics. In practicality, there is a constant need to update and scale content in an ever-changing environment.

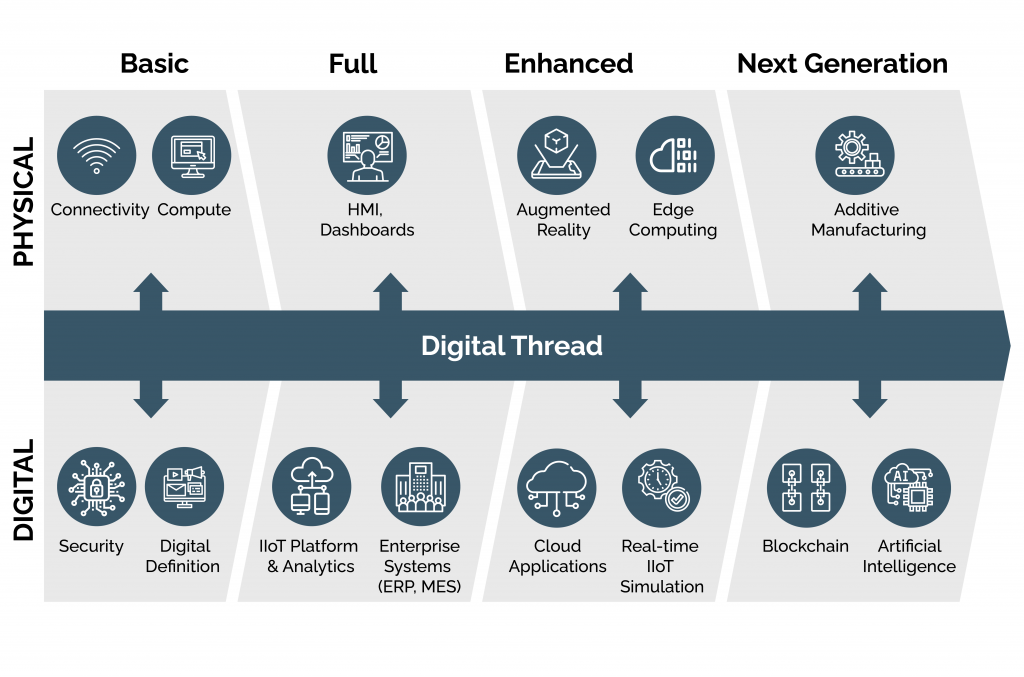

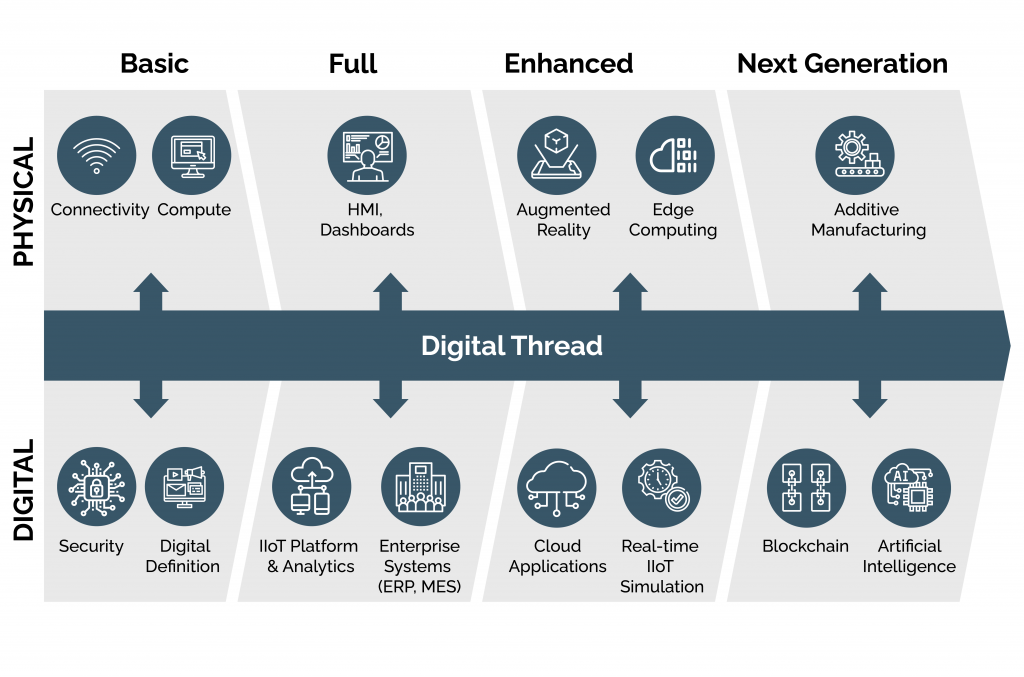

Live Digital Twin data offers a real-time view of internal processes and system statuses. Hence, the Digital Thread acts as a single composition of all the disparate digital identities within the physical system or operation.

Demonstration with the Volvo Case Study

The Volvo Group specializing in manufacturing trucks, construction equipment, and industrial engines employed Digital Twin and Digital Thread technologies to update and scale QA for AR experiences continuously. Each engine required 40 checks with about 200 possible QA variants that had to be executed in 8 minutes at the QA station. Usually, it took five weeks to train employees on this complex inspection procedure. So, Volvo combined Digital Twins and Digital Threads to establish and maintain data flow consistency and efficiency.