If minimizing failures, shortening development cycles, and smoothening the product development cycle are your paramount goals, then Digital Twin adoption should be your top priority. Digital Twin offers visibility on your production line and helps predict the future of various processes. It essentially helps maximize OEE, optimize productivity, and improve business profitability. In other words, Digital Twin empowers engineers to analyze, explore, and assess physical assets, processes, and systems using virtual tools. This ability helps gain a highly accurate view of what is happening now and what will happen next.

What is Digital Twin?

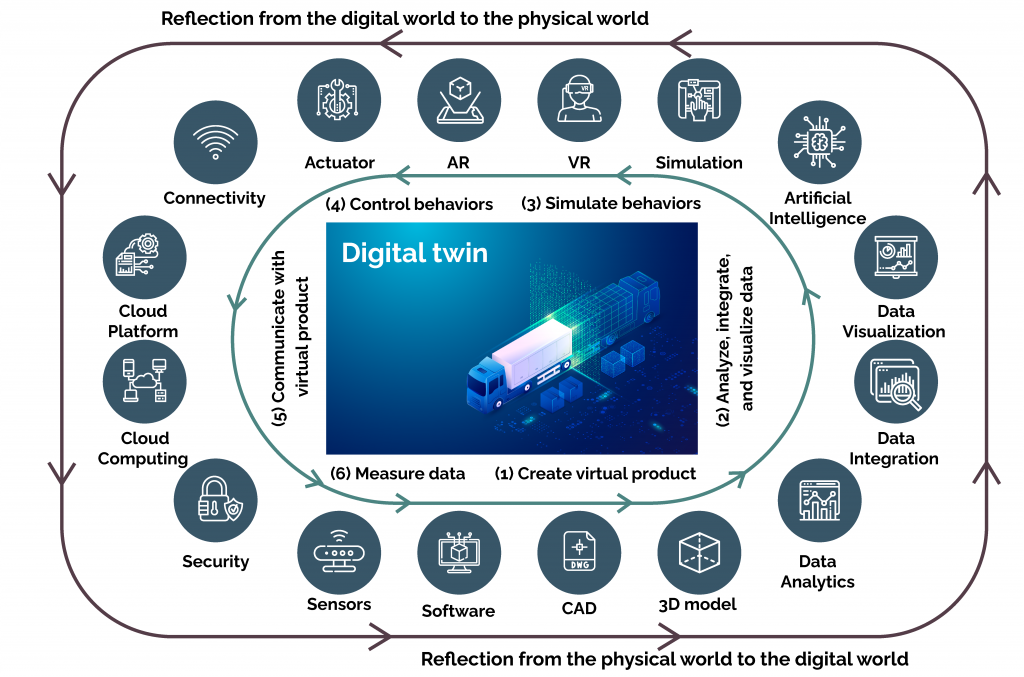

Digital Twin is a technology that engages AR, VR, 3D graphics, cloud, AI, data modeling, and other emerging technologies to build a virtual model of a system, process, product, service, or other physical objects. This virtual replica of the physical world gets updated based on real-time updates and environmental parameters.

‘Digital Twin’ is often mistaken for being a simulation. But, in reality, it merges business logic, IoT data, modeling and simulation, and Data Analytics to predict a physical system’s behavior. Converging virtual and physical worlds helps manufacturers and AR/VR businesses head off problems before they occur, prevent downtime, improve the scope of their products/services and even plan for the future by using simulations. A contemporary Digital Twin combines multiple interacting systems to account for different facets of the physical system.

Origins in Aerospace

Digital Twin’s origination can be traced back to NASA’s Apollo 13 mission. During the building process, NASA had built multiple simulators of various systems of the actual spacecraft that they initially used to train astronauts for failure management. Real-time data was used during an explosion in the oxygen tanks (which critically affected the main engine) to modify the simulators and emulate the damaged spacecraft condition. Instead of IoT, advanced telecommunications was used for two-way data transfer. Modified simulations provided critical information to the crew, ensuring their safe return to earth. Thus, NASA had nearly set up the modern-day Digital Twins framework.

Why Digital Twin is Helpful

The Digital Twin is used in specified analytics workflows to facilitate the planned business outcome, using consistently acquired environmental and operational data. The data flow consistency allows the Digital Twin model to continually adapt to environmental and operational changes and deliver the best results. Thus, the Digital Twin reflects the physical asset or system’s living model offering the near-accurate representation during development. This technology can be rapidly and easily scaled for a quick deployment for similar applications.

Digital Twin helps model at these levels:

- Component level – Focus is on a single, highly critical component within the manufacturing process/facility/production line.

- Asset level –A Digital Twin is created for a single asset within the production line.

- System-level – The Digital Twin helps monitor and improve a production line system.

- Product Level- This technology helps monitor and test a product in real-time as used by real customers or end-users.

- Process level – The Digital Twin focuses on optimizing processes like design, development, and production. It also relates to the distribution and consumption lifecycle of end-products and the development of future products.

Digital Twins allow engineers to test a physical product through virtual modeling and monitor which aspects may need to be improved, replaced, or augmented. It also helps evaluate the risks and issues that might occur in the future without ever using the product.

Additionally, Digital Twin can help:

- Enhance product traceability.

- Test, validate, and refine assumptions.

- Increase the level of integration between unconnected systems.

- Remotely troubleshoot equipment, regardless of the geographical location.

A digital twin performs real-time tests on a Minimum Viable Product (MVP), process, or system based on real-time updates (data and status) and real-world dynamics. The state of the Digital Twin changes as it receives new data from the physical object. As this model matures, it generates more accurate and valuable outputs.